Anaplan Use-Case 6: Override at Higher Level

We have heard about “override” both in business planning and in Anaplan world. Often, business users import some data and then override a few values of the sourced data, at the same level of dimensions, to create a new dataset. However, occasionally, users prepare/plan data at a certain level of dimensions and then override (aggregated) values at a higher level of dimensions, expecting the values at original/lower level to change accordingly. In this article, we exhaustively discuss the latter use-case.

NOTE: This article is a segment of the Anaplan Use-Cases Series. If you haven’t already, I encourage you to go through the introductory blog Why Anaplan Use-Cases Series? to understand the background behind this endeavor.

Context

A hypothetical firm DataByte manufactures and sells data-storage devices such as hard disks and solid-state devices. It has multiple manufacturing sites in various cities all over the USA.

It is the year 2024. Every year, in the month of March, Supply Management team goes through an arduous process of forecasting quantity of different products to be manufactured by each manufacturing site in each of the four future years. For each Product, Site and Year, Supply Quantity is projected using manufactured quantity in the past few years, a site’s current capacity for manufacturing each product and expected macroeconomic growth in the upcoming years.

While Supply Manager works on initial forecasts of Supply Quantity, he receives demand forecast numbers from the Demand Management team. Again, the forecasted Demand Quantity is meticulously prepared at Product and Year level by the Demand Manager using the latest feedback from the existing customers, open/pending sales pipeline, expected growth of the industry and competitive landscape.

To compare the supply forecast with the demand forecast, the Supply Manager first aggregates the forecasted supply data from Product, Site and Year level to Product and Year level.

Using the measure Variance %, Supply Manager then checks whether the forecasted supply is in the ballpark range of forecasted demand.

If Supply deviates from Demand significantly (i.e. if variance > 5% or < -5%), Supply Manager investigates further, and if required, would like to override the aggregated supply quantity, only to have the numbers at the original (lower) level of dimensions change accordingly. (The significant variances have been highlighted in red color, so that Supply Manager can quickly dive into further analysis.)

User Story

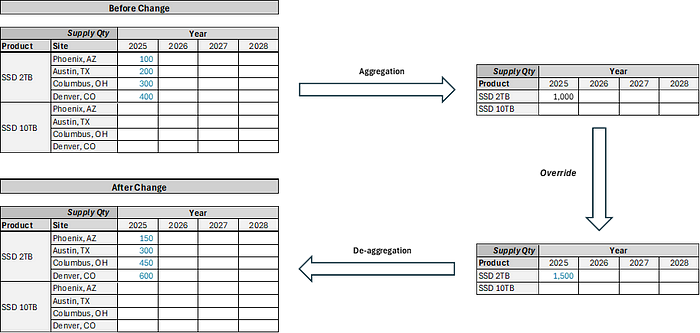

As Supply Manager, I want a capability to override forecasted supply quantity at product and year level and the overridden number to automatically apply (override) the original user inputs at more granular level (product, site and year) in the same proportion/allocation that existed before the change.

Notice that the proportion before the change (100:200:300:400 = 1:2:3:4) is same as that after the change (150:300:450:600 = 1:2:3:4).

Also, the user should be able to zero out the supply quantity, if needed.

Analysis & Design

The existing Anaplan model already has three modules.

INP01 Supply Forecast: Supply Forecast is input at Product, Site and Year level.

DAT01 Demand Forecast: Demand Forecast is imported and stored at Product and Year level.

RPT01 Supply vs Demand: Supply and Demand forecast numbers are compared at Product and Year level.

We need to take following actions to cater to the given business requirement.

A. Calculate Site Allocation % to store proportion of original supply quantity for each Product and Year allocated to different Sites.

B. Allow Supply Manager to input override numbers for Supply Quantity at Product and Year level in a new module INP02 Supply Override.

C. Compute new supply forecast numbers at Product, Site and Year level by multiplying Site Allocation % (at Product, Site and Year level) and Override Supply numbers (at Product and Year level).

The new supply forecast numbers can then be copied over to the original supply forecast through an import action.

Implementation

1) Calculate Site Allocation % in the INP01 Supply Forecast module itself. (Please note that a subsidiary view Supply @ Product, which holds the aggregated Supply, has been created for tidier explanation of the computation of Site Allocation %. Since the aggregated Supply already exists in RPT01 Supply vs Demand module, we should use that rather than Supply @ Product line item).

2) Create a new module INP02 Supply Override to let user input override supply numbers at Product and Year level.

User would need to select the Override? Boolean before inputting Override Supply number. Hence, we set up DCA on Override Supply line item based on Override? line item. This is to ensure the ask in the user story “Also, the user should be able to zero out the supply quantity, if needed.”

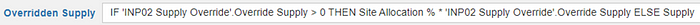

3) Calculate new supply numbers at Product, Site and Year level by multiplying Site Allocation % with Override Supply. We reuse INP01 Supply Forecast module to do so. Notice the use of If Then Else statement, without which the cells that did not belong to overrides would get zeroed out accidentally.

4) Set up an import action to overlay new numbers onto the old numbers.

Overridden Supply -> Supply

5) Remember to clear up and reset the module INP02 Supply Override. We use two new line items Falses and Zeroes and two new import actions to do so.

Zeroes -> Override Supply

Falses -> Override?

6) Place all the three import actions in one process.

7) Edit the existing app page to include the requested Supply Override capability.

Conclusion

There are a couple of things worth pointing out with the given requirement and existing solution.

1) We wouldn’t need to set up Override? Boolean, had the user not have the need to zero out the supply numbers through overriding mechanism. User could just input override numbers wherever applicable, and the multiplication formula would consider only greater-than-zero override inputs, as shown in the formula below.

2) However, due to specific ask, we did have to implement Override? Boolean concept. Interestingly, the concept comes with its own problem that user needs to be aware of, if he hadn’t thought of it before dictating the requirement. Once the override of 0 is applied, the system loses the proportion (Site Allocation %) completely for the given Product and Year. If user mistakenly overrode with 0, user would need to input supply forecast numbers at Product, Site and Year level all over again for the system to compute the proportion (Site Allocation %). Consequently, user would need to exercise extreme caution while zeroing out the supply forecast through the override mechanism. If it helped, we could highlight cells (perhaps, with red color) that have zero overrides, arresting user’s attention before he pressed the Override button.